[Authentic 15'' Identification Guide] Look for the Core Brand Logo of BOE

Release time:

2025-09-08

Let's jointly boycott counterfeit products and safeguard a healthy, orderly market environment.

As liquid crystal display technology becomes more widespread and market demand grows, 15-inch 1024* The 768-resolution LCD display, with its stable performance and highly adaptable size, has become a widely used display component in fields such as industrial control, medical equipment, and security surveillance. However, the global market is currently flooded with counterfeit products mimicking this BOE model. These high-quality imitations closely resemble the genuine BOE product in appearance, making it difficult to distinguish them simply by visual inspection. This poses significant procurement risks for downstream manufacturers and buyers—potentially leading to end-device failures due to substandard product performance, while also jeopardizing the valuable business partnerships built on the trusted reputation of the BOE brand. To help partners accurately identify authentic products and avoid falling into counterfeit traps, this article will focus specifically on the BOE 15-inch 1024* 768 The key distinguishing features of the LCD display, along with its outstanding mass-production quality performance.

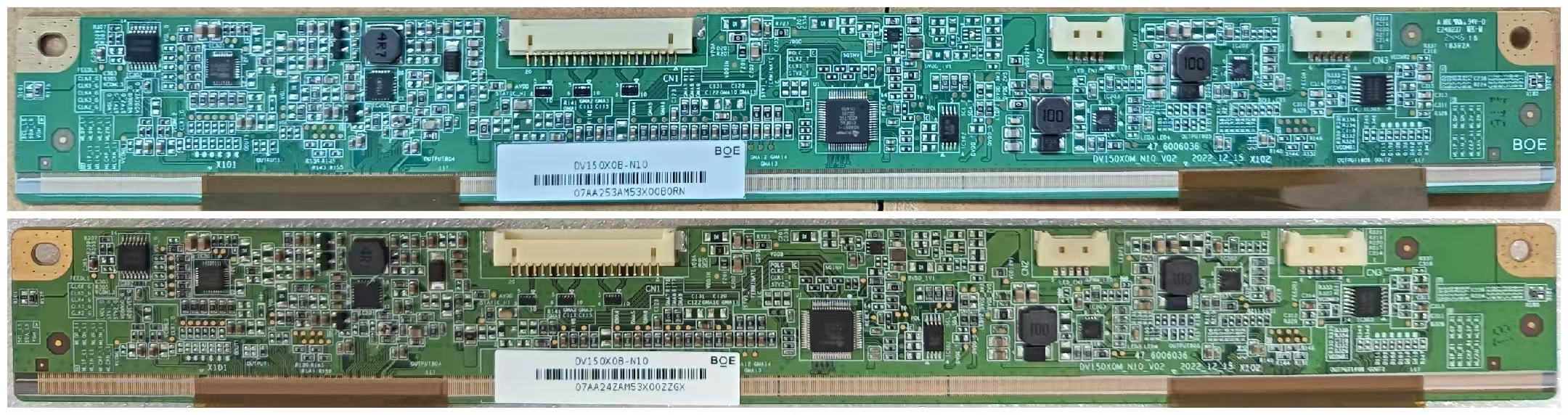

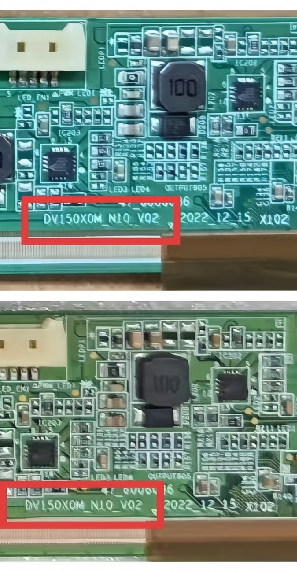

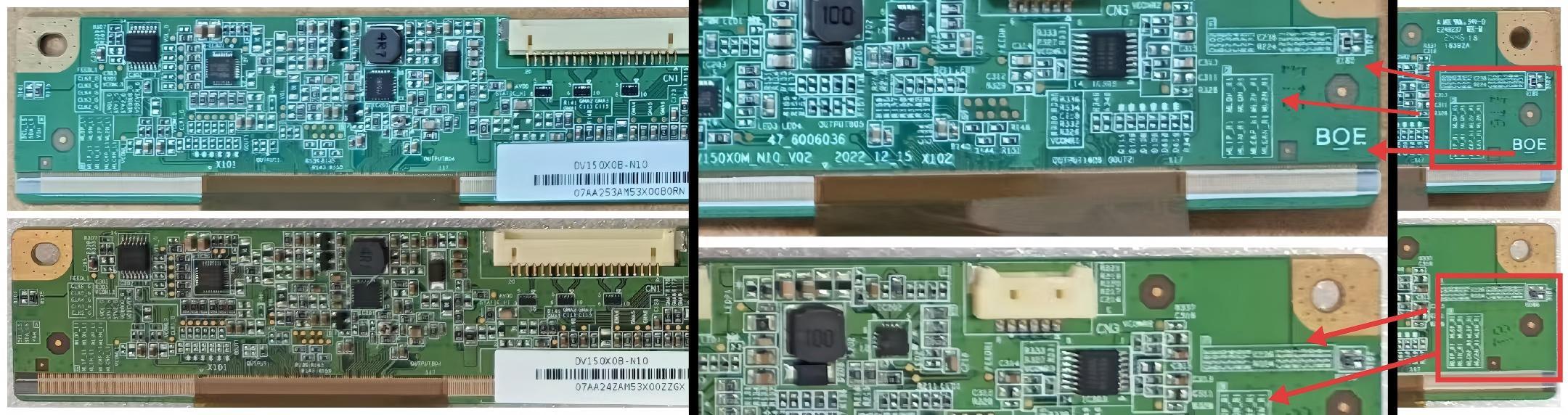

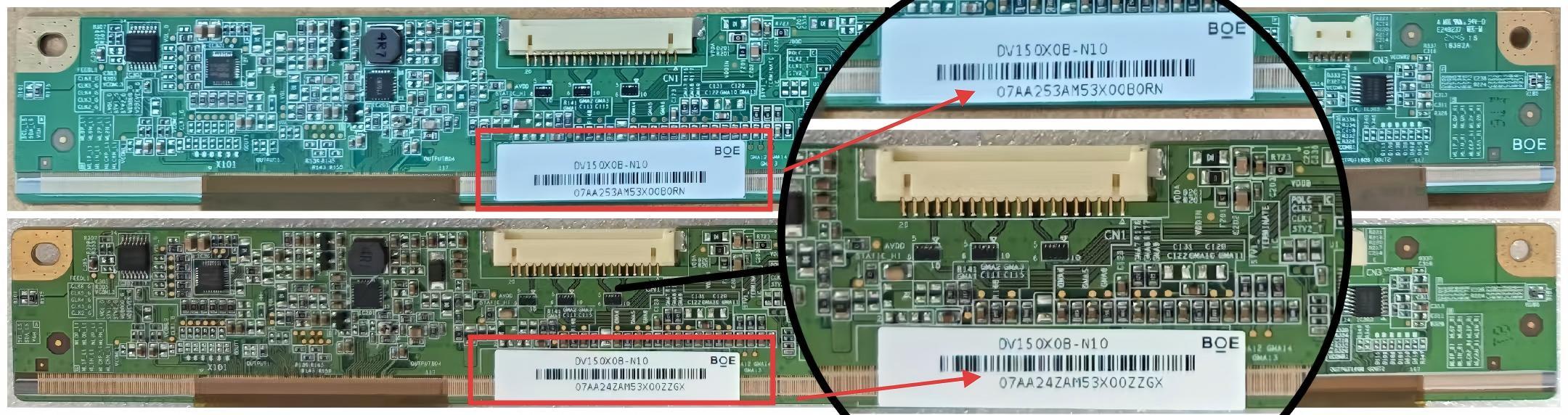

I. Core Identification: For the T-con board PCB's critical components, only the following two reference images indicate genuine products (the product is authentic only if all five positions match exactly).

All the images above are genuine products.

- Disassembly Preparation : Carefully remove the display's LVDS data cable while ensuring the display is powered off;

- Remove Myra's protection : The surface of the T-con board is typically covered with a protective Mylar film—designed for insulation and dust prevention. Gently lift the edge of the Mylar with tweezers, then slowly remove it entirely, revealing the underlying PCB board itself.

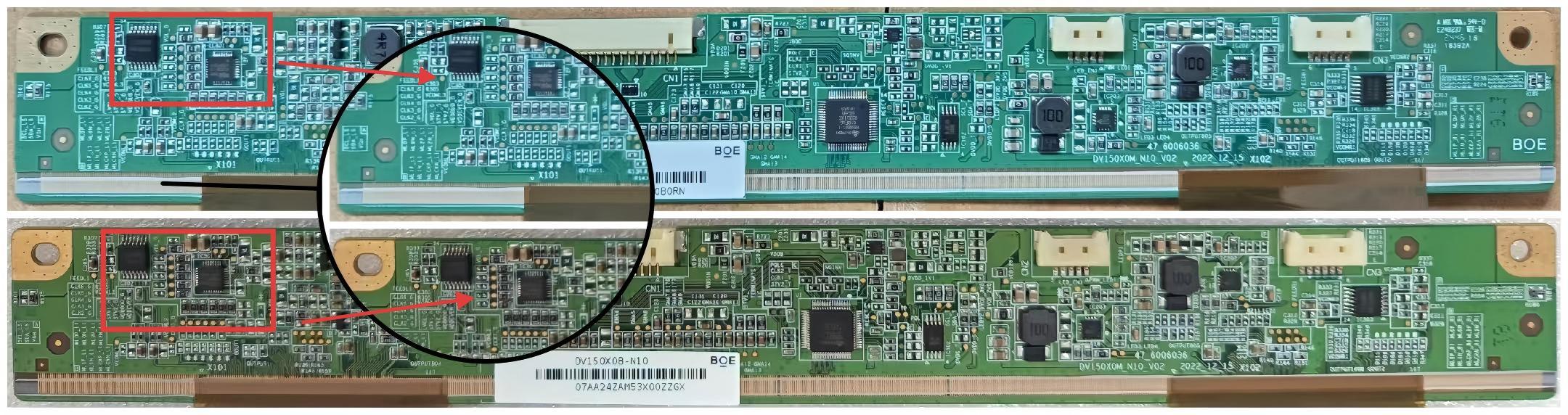

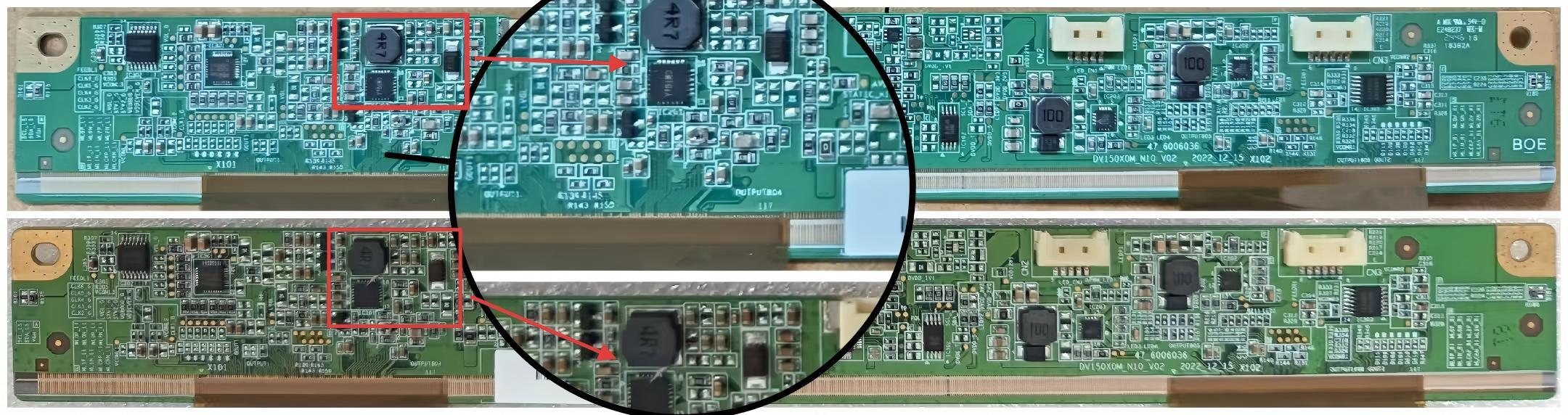

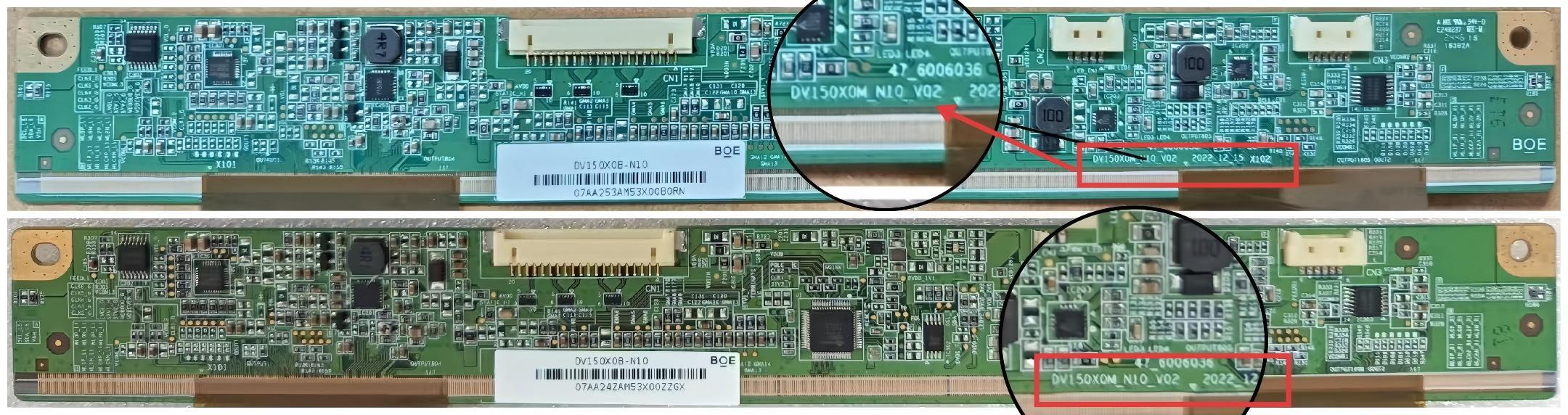

- Focus on Key Identifiers : Carefully examine the surface of the PCB board, especially the area marked by the 【red circle】 (supplement according to the actual illustrated location, such as the corner of the PCB board or around the chip) — this area features BOE’s exclusive process marking for mass-produced products, characterized by the following:

Step-by-step illustrations of the key areas on the PCB board, highlighted with red circles and magnified details 1

Detailed image under magnification 1

Step-by-step illustrations of the key areas on the PCB board, highlighted with red circles and magnified details 2

Detailed image under magnification 2

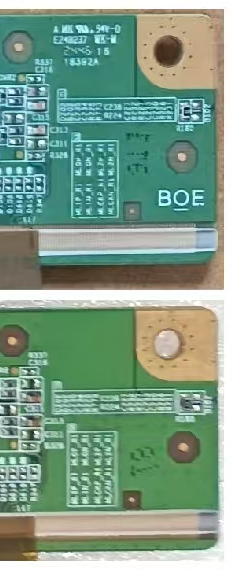

Step-by-step illustrations of the key areas on the PCB board, highlighted with red circles and magnified details 3

Detailed image under magnification 3

Step-by-step illustrations of the key areas on the PCB board, highlighted with red circles and magnified details 4

Detailed image under magnification 4

Step-by-step illustrations of the key areas on the PCB board, highlighted with red circles and magnified details 5

Detailed image under magnification 5

- Source control : Core materials such as liquid crystal panels and driver chips are either independently developed by BOE or custom-designed through deep collaboration with leading suppliers, effectively mitigating material defect risks from the source.

- Process Control : Utilizing an automated production line for critical processes such as PCB soldering and module assembly, equipped with an AI-powered visual inspection system capable of instantly detecting process defects as small as 0.01mm, ensuring consistent quality across every single product;

- Full Lifecycle Testing Before mass production, the product undergoes more than 20 reliability tests—including high- and low-temperature cycling, humidity aging, and vibration/shock testing—to simulate performance under extreme usage conditions. During mass production, a quality control process is implemented: "hourly sampling inspections paired with daily full-scale rechecks" to ensure no defective products make it to market.

Key words:

Elevator Ship Robot Medical Device Semiconductor Manufacturing Device

Related News

Highly Recommended | PV121X0M-N10

2025-09-01

Premium Recommendation | DV215FHM-NN0

2025-08-18